Revolutionizing 3D Printing: How Nefilatek Uses Recycled Plastics and Advanced Automation Technology

Automation of a 3D printer filament extrusion line | Nefilatek

Computer vision | OpenCV | Projection mapping

Project

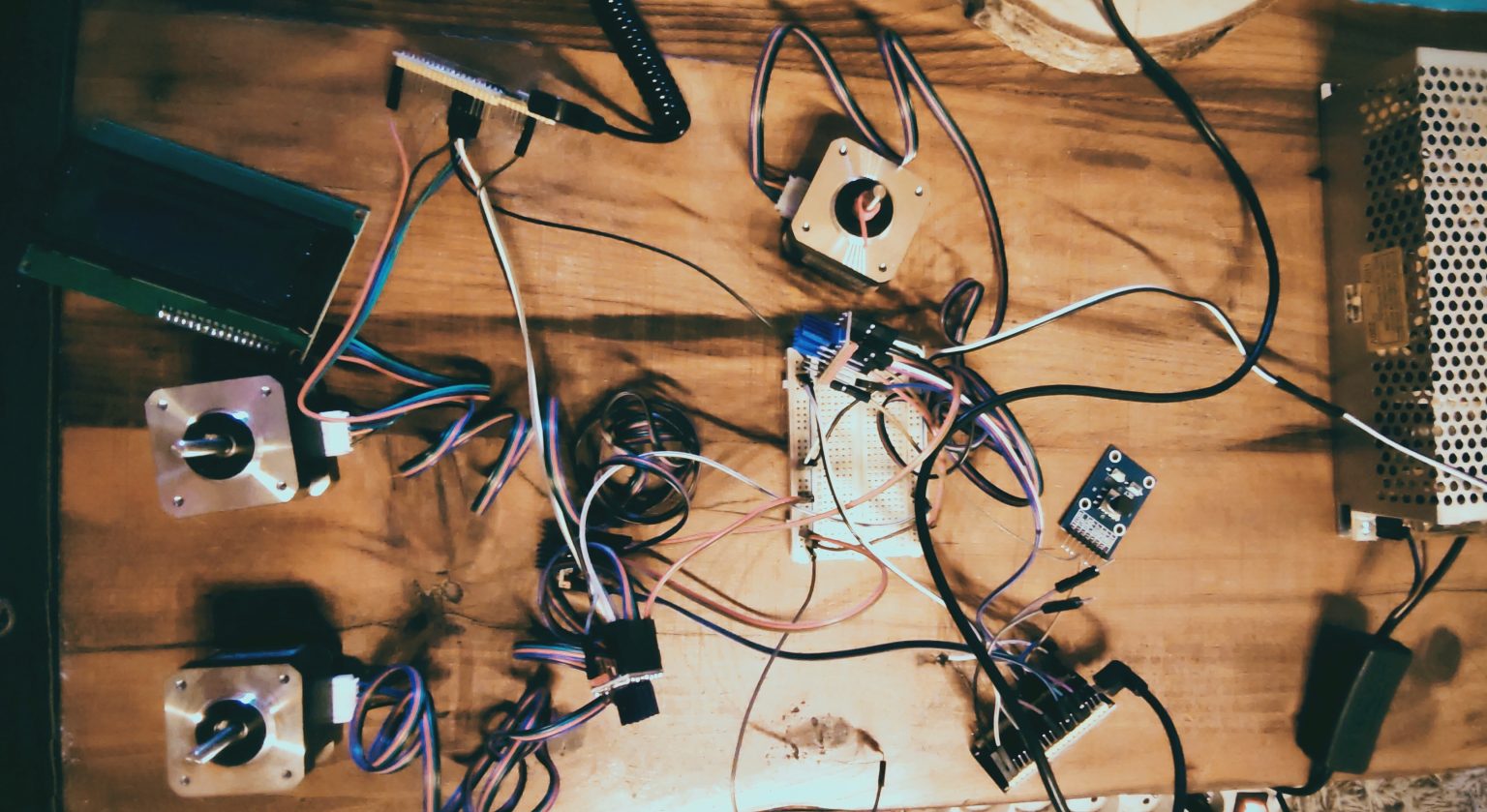

Nefilatek is a company specialising in the manufacture of plastic filament spools for 3D printers, with the distinctive feature of using only recycled plastics. Created in the wake of the growing popularity of 3D printing, Nefilatek has had to carry out a great deal of R&D to create and improve its entire production chain, enabling it to extrude new types of plastic.

Among the features developed by TorrusVR :

- Wireless stepper motor control (WiFi, MQTT) with PID feedback.

- Reading of sensor data (laser, limit switch, optical encoder).

- Plot and export graphs and statistics for quality control.

- Web interface for control and data display.

- Physical control module with buttons, encoder and LCD screen.

- Remote access for updates and after-sales service.

For this project we provided the customer with both a hardware and software solution, with software embedded in micro-controllers developed specifically for Nefilatek’s needs. The design choices made the solution scalable in the future, with the possibility of adding numerous wireless sensors and actuators and centralising data and control on a local server.

Thanks to this solution, Nefilatek has significantly reduced its handling requirements and can increase its production by accelerating extrusion speed. In addition, this automation solves a number of problems specific to the extrusion of plastic filament, identified in advance by the customer.

For more technical information on the type of solution implemented, see this article describing the use of the same technologies in another context.

Do you have a project or need information?

Don’t hesitate to contact us!

![]() contact@torrusvr.com

contact@torrusvr.com

![]() Bordeaux / Paris (FRANCE)

Bordeaux / Paris (FRANCE)

Development of Immersives Technologies

Site map

Home

Services

Portfolio

Action Game

Immersicase

Blog

Legal Mention

Immersives Technologies

Virtual Reality (VR)

Augmented Reality (RA)

Metaverse

Computer Vision

Projection Mapping

Video Games

Contact

contact@torrusvr.com