Revolutionizing the Agricultural Industry: Automated Corn Traceability with Adourebro and TorrusVR

Collaboration and innovation in corn shelling

Internet of Things (IoT) | Software development

Concept

Intuitive traceability software

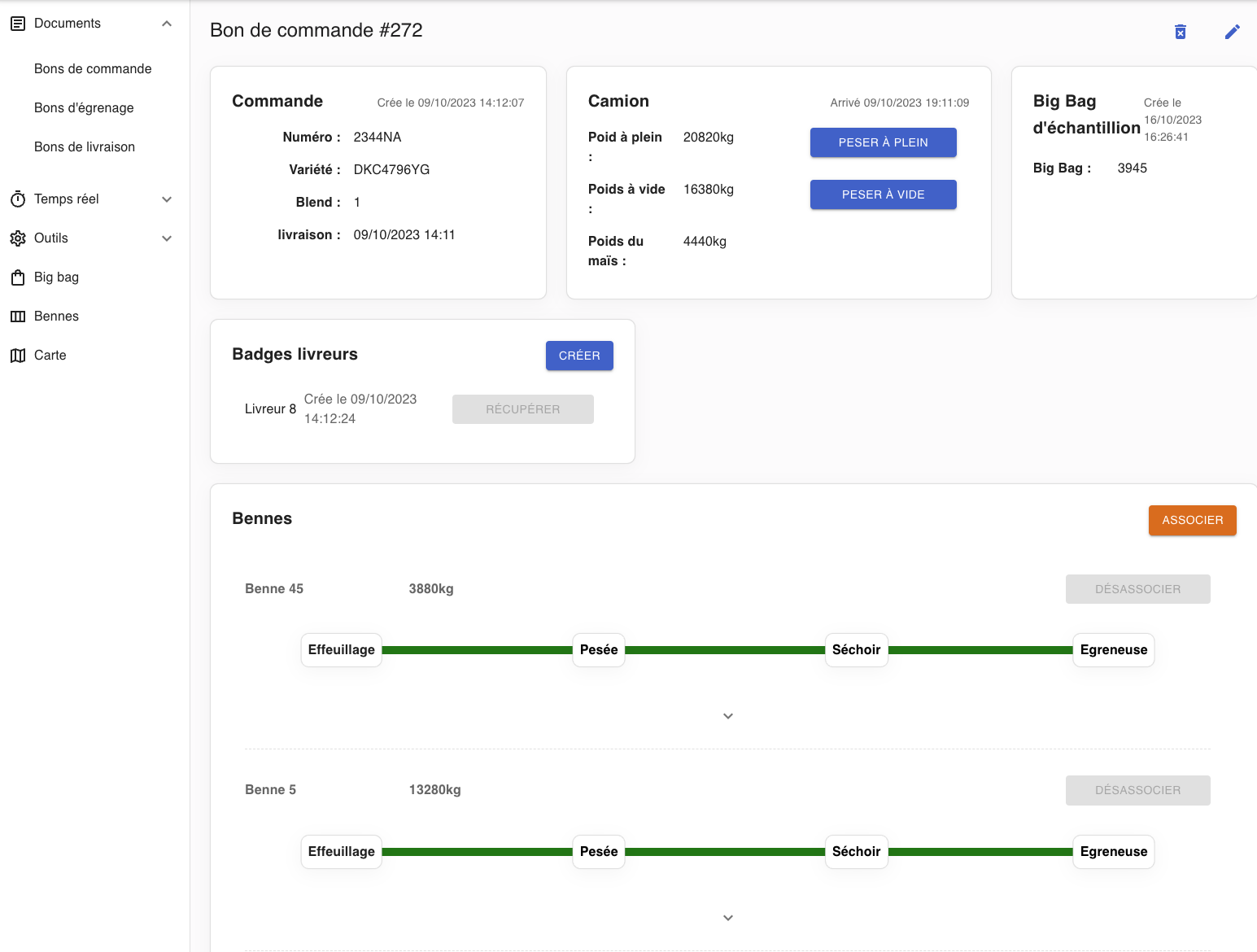

That’s where we came in, to design simple, intuitive traceability software specifically tailored to Adourebro’s needs. The aim was to simplify the tracking of maize from the field to the factory, eliminating the possibility of human error.

The software developed by TorrusVR has enabled Adourebro to automate the tracking of maize at every stage of the process, from weighing to shelling. Employees now have a user-friendly tool that enables them to enter maize data quickly and accurately, improving product traceability.

Data analysis for better management

In addition to improved traceability, the software also enables the data collected to be analysed. For example, it can generate drying curves based on daily samples, providing valuable information for optimising the drying process.

The software can also be used to generate order forms, delivery notes, scan QR codes generated by the system and much more!

IOT & Industry 4.0

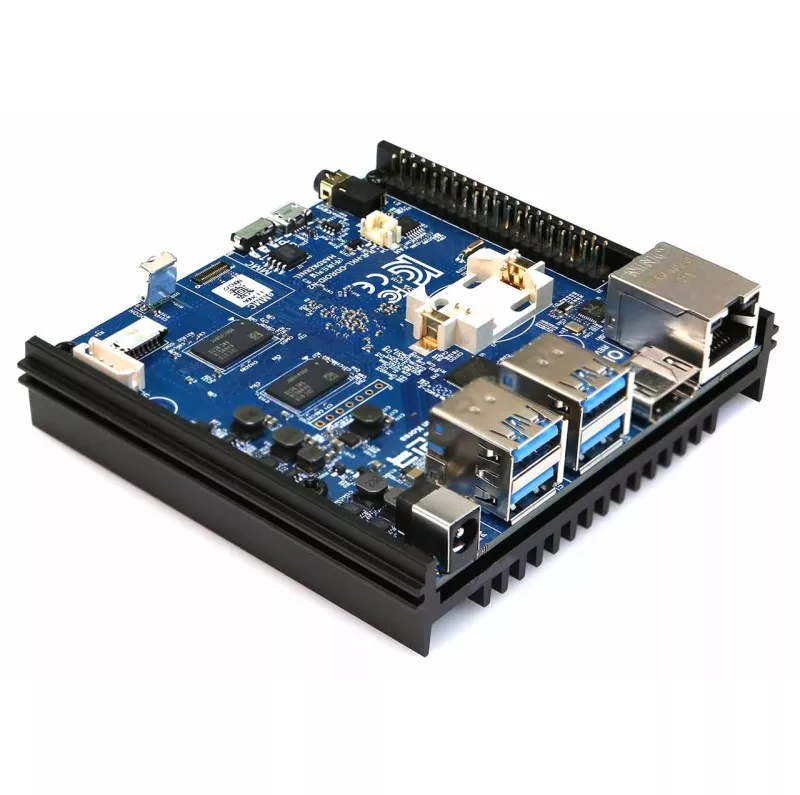

To ensure the traceability of the skips transporting the maize from one machine to another, we fitted each skip with an RFID badge and installed long-range RFID readers at each point of passage. In all, more than 100 skips and 80 RFID readers were installed outdoors!

We interfaced the RFID readers and machine control relays with a dozen IOT Gateways (mini PCs) using software we developed ourselves in C# and a Docker environment for greater portability.

All the data is collected in a local database on site, as the system has to operate entirely offline due to the quality of the Internet network. All the backend and frontend are hosted locally, with remote replication and a remote access system.

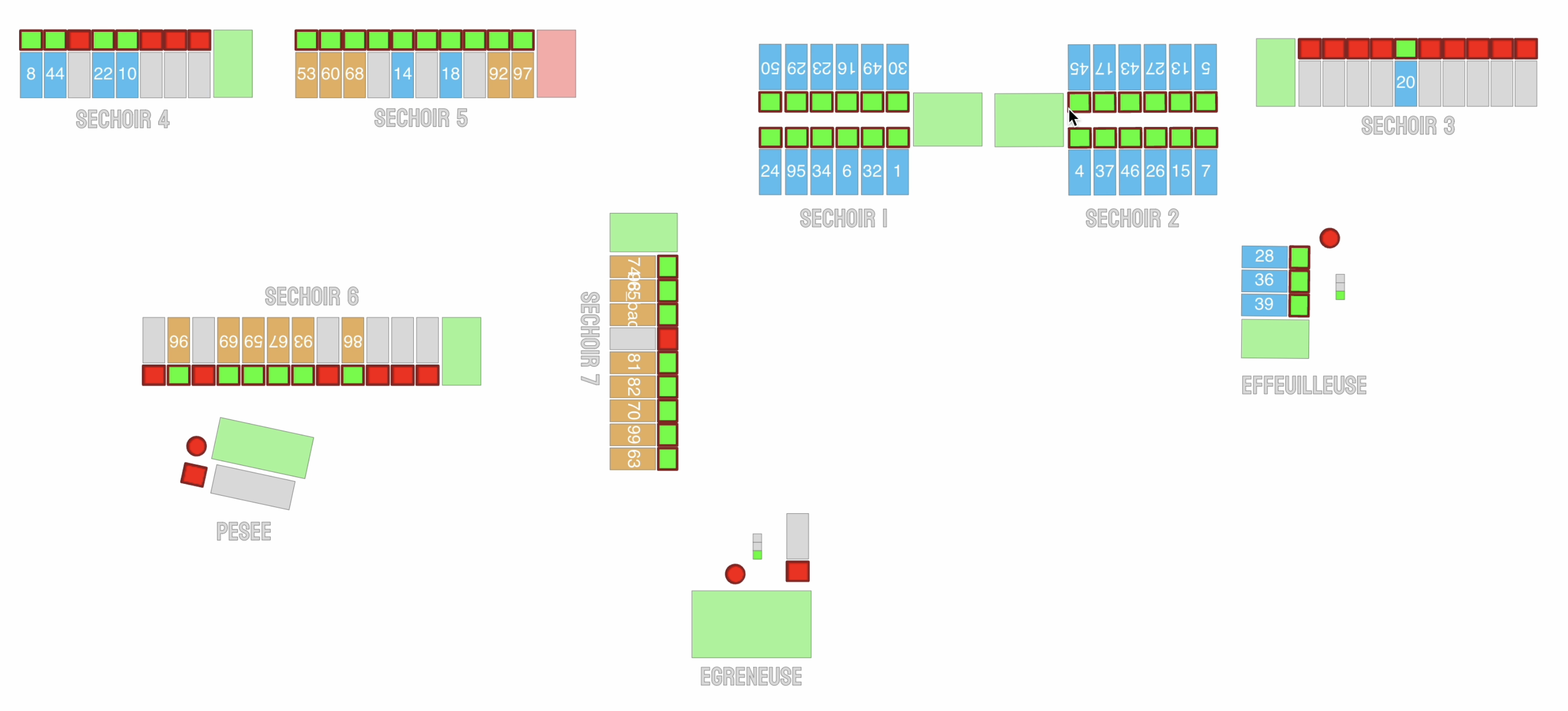

The user interfaces are developed in React JS, and below is an example of the interactive mapping that provides information on the status of the system, the status of the machines, and the location and contents of the skips.

Simulation with Unity3D and Docker

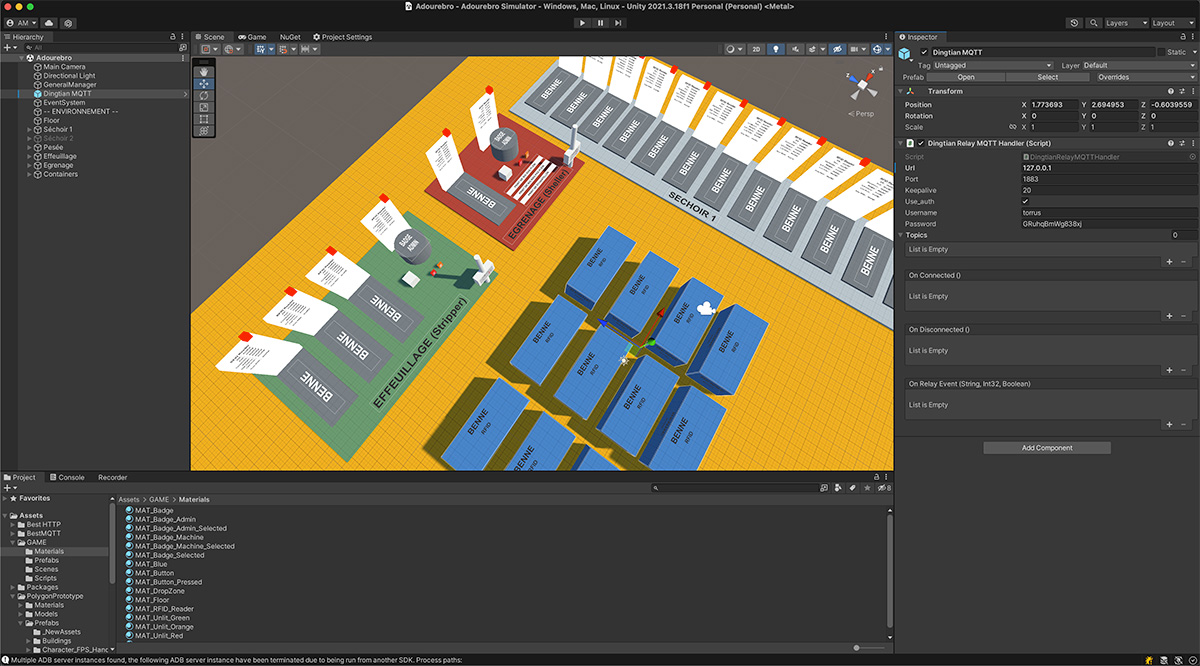

This project required the installation of a lot of hardware (80 RFID readers, 10 mini PCs with the entire WiFi network). With only 4 months to deliver the project, we couldn’t wait for the installation to be finished before starting the tests. What’s more, the on-site tests were very complicated to set up because we needed a driver to transport the skips from one place to another. There was no room for error!

Our experience in the world of video games came in handy! In just a few days, we developed a simulator on Unity 3D capable of simulating RFID readers and relay and I/O systems, by imitating their communication protocols (MQTT and TCP/IP). Thanks to this simulator, we can move the skips in just a few clicks, manage the RFID readers’ fields of action and pass RFID badges to administer the system.

The simulator is highly versatile: it can be used either in full simulation by communicating with the software on Docker, or in partial simulation by communicating directly with the mini PCs. It’s even possible to mix virtual RFID readers with real readers installed in the lab! This meant that the simulator could communicate with the backend and we were able to test the machine management software upstream, validate the state machines, test the interactive mapping and correct most of the errors before the end of the installation

Conclusion : A successfull collaboration

Do you have a project or need information?

Don't hesitate to contact us !

![]() contact@torrusvr.com

contact@torrusvr.com

![]() Bordeaux / Paris (FR)

Bordeaux / Paris (FR)

Development of Immersives Technologies

Site map

Home

Services

Portfolio

Action Game

Immersicase

Blog

Legal Mention

Immersives Technologies

Virtual Reality (VR)

Augmented Reality (RA)

Metaverse

Computer Vision

Projection Mapping

Video Games

Contact

contact@torrusvr.com